I just want to add a little explanation about three-way solenoid valves to help people understand how they work in coffee machines and the problems you might see.

In many commercial coffee machines, this solenoid valve is threaded directly into the group through copper bass holes.

This solenoid valve has two functions:

1. Start and stop the flow of brewing water

2. Exhaust excess pressure once the shot is complete.

The valve consists of four main components:

1. Coil (black box).

2. The valve guide "stem".

3. Valve guide "base".

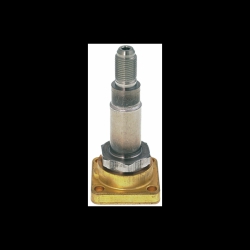

4. Valve "nucleus" (pictured).

The core is enclosed in the solenoid valve guide and slides up and down in the guide. Take a look at the nucleus, notice the springs around it, the running and descending grooves, and the round red valve seal. There is a second red seal on the other end of the core.

Also, take a look at the valve guide picture, pay attention to a large hole "valve stem" at the end of the valve guide. This is the exhaust port, which we call port 3.

The bottom of the valve base is shown. Note that the port numbers are 1 and 2.

Most commercial and some home espresso machines are connected by pipes. When they are there, there is always some water pressure in the heat exchange system or coffee furnace. Before entering the valve at port 2, brewing water circulates through the pipes and channels in the group.

When the machine is turned off or idle, the spring on the valve core pushes the red seal to the valve seat in the base, closing port 2 to prevent water from entering the valve.

The barista presses the button of the coffee pot and starts making coffee. The coil generates a magnetic field, sucking the nuclei away from port 2. This causes water to flow into the valve and out through port 1. From there, water flows through the group and out of the dispersed screen, where it encounters ground espresso.

One thing to note is that port 1 (the port leading to the scattered screen) is always open.

In this way, the solenoid valve has completed its main function-start and stop the flow of brewing water.

Recall that another function of this solenoid valve is to release excess pressure in the brewing chamber at the end of shot peening. Port 3 is an exhaust passage.

Remember, when the barista presses the button to start shooting, the core will move away from port 2. When closed, close port 3. This prevents the water now flowing through the valve from escaping from port 3. When the shot ends, the nucleus moves back to port 2 and opens port 3. This causes any pressurized water remaining in the door filter basket to flow back through the orifice 1 to the valve, through the groove on the side of the valve core, and then out through the orifice 3.

When the valve is working properly, only two of the three ports are open at any one time.

Although these are fairly high-quality components, failures are common. Frequent use and constant exposure to hot water and waste coffee will cause a rather harsh operating environment.

How could these valves fail? Coils fail. Accumulation of damage to valve seals and valve seats usually prevents their complete sealing. Sometimes the nucleus will "freeze up", which will prevent it from opening. Nuclear springs sometimes break due to fatigue and aging. Debris or deposits can also block one of the valve ports and prevent water flow.

The troubleshooting of the coil is very simple. If the coil is “on” and the power received is equal to its rated value (20V, 110V, or 208-240V), when you (be careful), you should feel a little pulling force and tap the valve with a screwdriver the end of the catheter. No pull? Bad coil.

Seal failure causes the valve to leak water, which usually flows out of port 3. A leak when the machine is idle indicates that there is a problem on the port 2 side, and a leak when pulling the snapshot indicates that there is a problem on the port 3 side. Sometimes the problem can be solved by disassembling and/or cleaning the valve, other times it needs to be replaced.

There are two ways to extend the life of the tee solenoid:

1. Backwash regularly with good espresso cleaner. Only use products labeled "espresso machine cleaner", Cafiza, Puro Caf, etc. Follow the manufacturer's recommended procedure (though you should use less detergent, a dime-sized amount is adequate). Please recoil frequently.

2. Make sure your water is "safe" for your machine. Manufacturers usually recommend that the hardness of water does not exceed 2-3 grains. Use appropriate filters and/or softeners and maintain according to the manufacturer's recommendations. Test your water to make sure it is suitable.

The water dispenser angle solenoid valve manufacturer hopes this article can help you understand the components and functions of the three-way solenoid valve.

Previous: Cautions for Solenoid Valves